ΑΙhub.org

AI4Industry pilot releases first demonstration video

By AI4EU’s AI4Industry pilot team

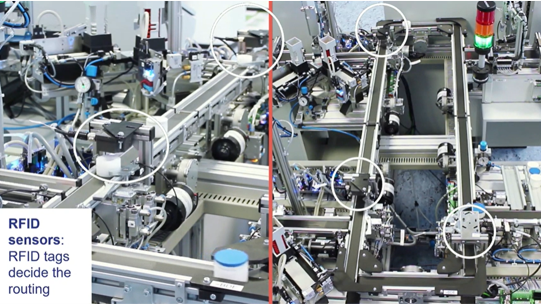

AI4EU’s pilot AI4Industry released its first video to demonstrate how AI techniques can help develop flexible and transparent manufacturing. The techniques, including semantic technologies, answer set programming, and machine learning, are demonstrated in an experimental plant provided by Evosoft.

The AI4Industry pilot aims to create a tool that assists engineers in production planning, getting insights about potential problems in manufacturing, and estimating the time needed to complete an incoming product request.

The tool consists of 3 main parts: skill matching and explanations, planning, and time prediction. Skill matching represents producibility checking, i.e. checking whether a certain product can be produced by the set of available machines in the factory.

The explanations function provides a list of statements that presents the reasons why a certain product cannot be produced, essentially explaining to humans why production stops. The planning function creates a list of steps that are needed to manufacture a product. Introduced as a small modification to the planning technique, the plan repair program provides explanations to humans of issues in the factory or the production goal.

Finally, how does the planner know how much time production will take? The time prediction component, which based on a machine-learning algorithm, estimates the production time per product. We show the experimental factory of Evosoft producing caps on cans with different colours and the results of these methods in a basic mock-up UI.

The AI4Industry pilot, a collaboration between Siemens AG, TU Wien, and Fraunhofer IAIS, is one of the eight pilots to be carried out during the lifetime of the AI4EU project to provide insights on real scenarios in the selected areas.